- Home

- Products

- Hydraulic Hose Crimper Machine and Crimping Equipment

- Heavy Duty Crimping Machine for Hydraulic Hose

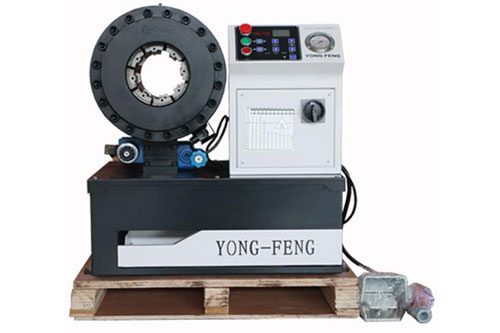

Heavy Duty Crimping Machine for Hydraulic Hose

-

- The crimp force of YONG-FENG Y160 uxtra thin radial hydraulic hose crimping machine is 2800kN, with a crimp range of 4~124mm and 11 sets of standard dies. YONG-FENG Y160 crimpers are widely used for crimping high-pressure fuel pipes, industrial hoses, water hoses, automobile air bags and ropes, metal pipes and steel tubes etc.

Operation:

The oil pump is immersed in the hydraulic oil inside the oil tank for cooling and silence. The oil pump is driven using electric motor and the hydraulic oil is pumped out and pushed using the plunger in the oil tank. As a result, the die set compresses in a radial direction and crimps the hose connector. When the compression amount reaches the predetermined value, the compression will automatically stop. The magnetic reversing valve then switches direction and the plunger moves backwards. As a result, the die set expands and the hose crimping process is finished.

Material:

The oil cylinder cover, oil tank and piston rod are made of 40 chromium, with a surface hardness of HRC26-30 and an operation layer hardness of HRC59-63. The hardened layer is 2mm thick. The 40 chromium is high pressure resistant and tear resistant with a great impact absorbing and carrying capacity. Therefore, the oil tank and piston rod are more durable.

Die connection:

Our crimping dies are connected through magnetism, which make it convenient for assembly and disassembly. The magnetic connection allows for automatic positioning, and the crimping is neat and nice. The dies are made of Cr12 die steel. (Cr12 die steel is a classic alloy tool steel.)

Hydraulic conduction system:

With the pipeless valve block connection, the hydraulic conduction system is oil tight and durable with little heat, stable pressure conduction and great longevity, and greatly improves the performance of the crimping machine.

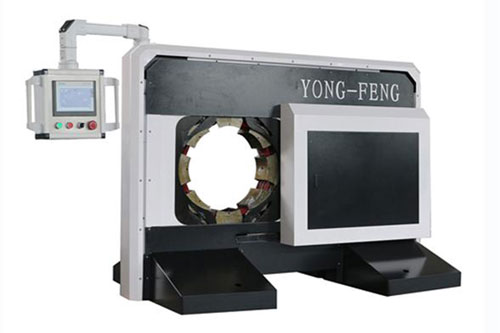

Our heavy duty crimping machines for hydraulic hose include fully automatic hydraulic hose crimping machines, digital controlled hydraulic hose crimping machines, ultra-thin hydraulic hose crimping machines and side feed hose crimping machines.

Shandong Yongfeng Hydraulic Machinery Co., Ltd.

Address: Beicheng Subdistrict, Economic Development Zone, Weifang City, Shandong Province, China